Correctly installing a gas ducted heater.

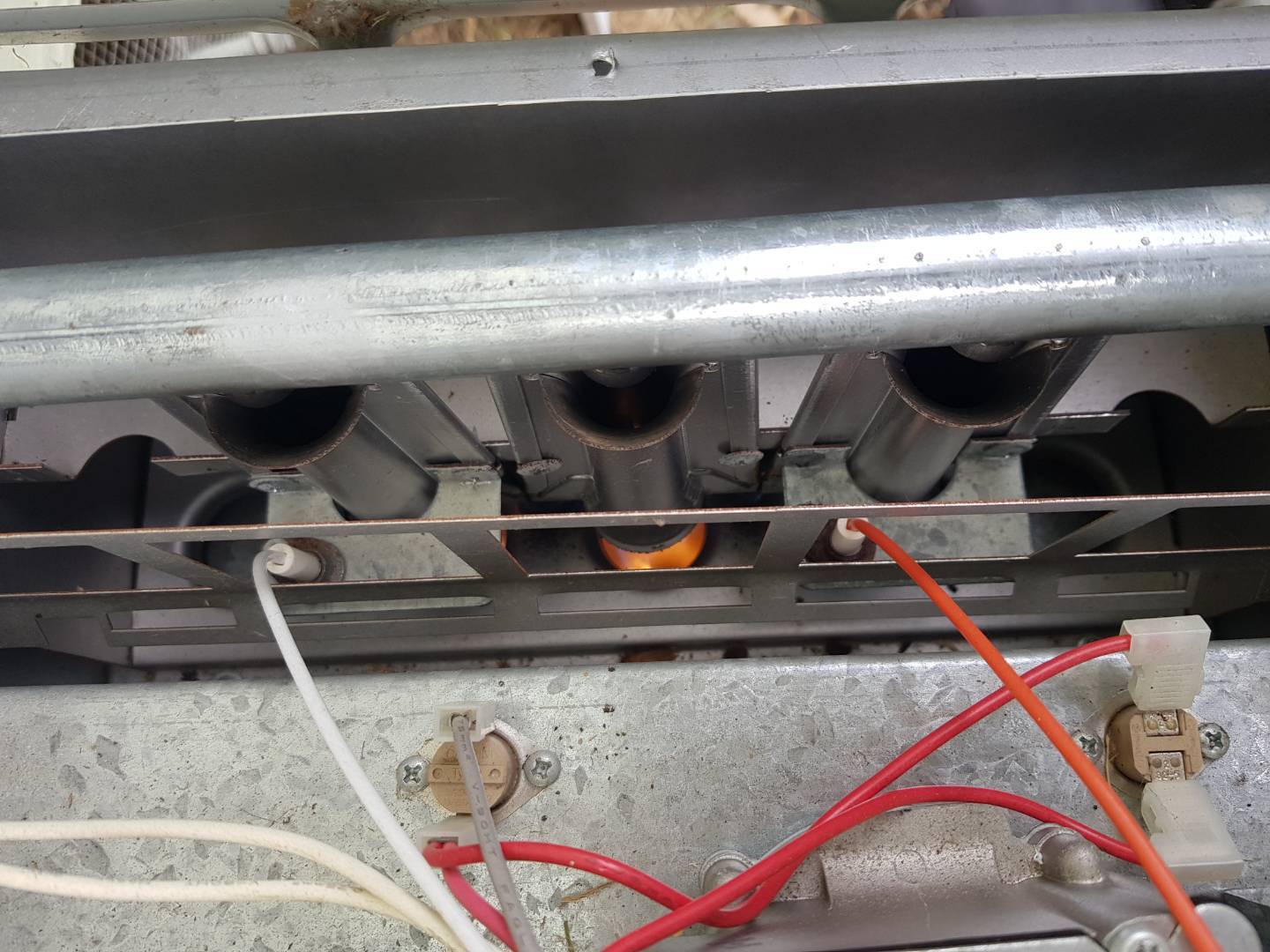

In the photos and the short movie, you will see a yellow flame. This flame is a soot-producing flame. With our modern tubular heat exchangers, everything has to be right to produce a beautiful BLUE flame.

In this particular case, the external gas ducted heater is running on LPG fuel. With gas bottles, a lot of people do not know that the bottle regulator has to be changed every 5 years. The spring tension drops off and it stops supply the correct pressure to the appliances, this drop in pressure has caused the gas valve to drop in burner pressure, then over time the flames change colour and burn yellow. This yellow flame then produces carbon or soot which blocks the secondary heat exchanger. This blockage then creates a secondary reason for the yellow flames and a lack of heat generated to the exchanger and the house.

Once this process starts it accelerates very quickly (about 4-5 days) blocks the heat exchanger completely, flames then cannot be drawn through the heat exchanger, flames then roll out of the enclosed burner area, which triggers a safety switch. This switch tells the control board of a dangerous situation and will not allow the machine to operate. The fix is a whole new exchanger or in most cases the price to do this repair leads to a better option of a new heater.

The second reason that LPG heaters run low on pressure is that the gas bottle gets to below 30% of it capacity. At this level it cannot supply correct burner pressure and the above situation occurs.

Both these situations upset customers. A person buys a product that is designed and or recommended to be installed. What fails to happen is REGULAR maintenance. It all seems such a waste of money.

Complete the form below to get a FREE no obligations quotation on any of the services we offer.